What are the oxygen transfer points during barrel ageing?

The proportion of oxygen transfer is not fixed over the entire duration of the ageing process. Its behaviour varies depending on several parameters, including:

- The extent to which the barrel is impregnated

- Whether or not the barrel is opened regularly

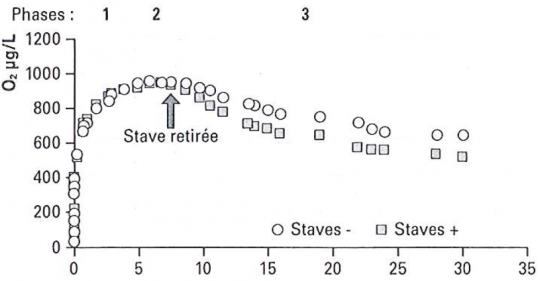

The barrel's oxygen transfer points are distributed over three zones: the bunghole, the joints between the staves and the pores in the wood. Depending on the stage of ageing, the proportion of each varies.

As an example, here are the proportions for ageing with the bunghole on top during the first six months. There is no opening for topping up, so the conditions are stable.

| Circulation area | Percentage of total oxygen |

|---|

| Bung hole | 0.21 |

| Spaces between the staves | 0.63 |

| Wood pores | 0.16 |

Note that the results would be different in a situation where, for example, the bunghole was opened every 15 days for topping up.

To significantly modify oxygenation, it is possible to choose different grains of wood or to change the location of the barrel and particularly the type of bung. The type of bung and its position has a major impact on the oxygen supply:

| Position and bung type | Oxygen supply mg/l/an |

|---|

| Wooden bung on the top | 28 |

| Wooden bung on the side | 36 |

| Silicone bung on the top | 45 |

It is clear from these results that the choice of bung and position is a fairly simple tool to use if a change in the oxygen supply is desired.